Table Of Content

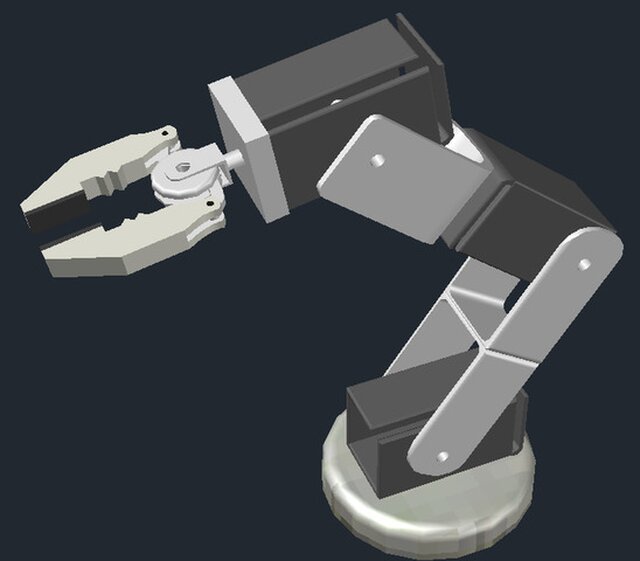

For welding, material handling, pick-and-place tasks, and dispensing, articulated arms are perfect. There is essentially no place in their work envelope that they cannot reach because of their multiple axes and degrees of freedom. As a result, articulated robots are among the most adaptable, flexible, and space-saving designs available. It's crucial to keep in mind that articulated robots are by nature dangerous. It may be more dangerous for operators to install an articulated robot in a situation where there is no risk mitigation.

Cylindrical Arms

Some applications require a human-robot mix to operate at peak efficiency. Collaborative robots are positioned to handle these types of applications. Material handling applications often deploy collaborative robot technology. This means a human operator can load raw materials into a staging area near the cobot while the robot handles the loading and unloading of the material into a machine. Cylindrical robot arms are designed around a single arm that moves up and down a vertical member. These robots are very compact and are deployed for small and simple tasks.

China Advances in Laser-Powered Submarine Technology

During the execution of commands, all angles formed by motor, forearm, arm and rod are slightly modified. To avoid stress in the components, all of them must be fixed in pivoting joints. It requires fine measurements for alignment, not to mention enough space for the rod to extend. There are free online apps to calculate torque for robotic arm joints [4]. You need to provide inputs, such as the configuration of the robotic arm (how many degrees of freedom it has), link lengths, link weights, loads and so on. The DC motor at joint 1 is a generic JGY370 DC motor [1] that spins at 6 RPM when powered with 6 VDC.

The 10 Coolest DIY 3D Printable Robotic Arm Projects

They offer high speed and precision in a horizontal plane while maintaining rigidity in the vertical direction. Cartesian robotic arms, or gantry robots, utilize a cartesian coordinate system (X, Y, Z) for movement. They feature linear motion along each axis, providing precise and predictable movement in a structured environment. To provide a better understanding, we have explored the various components, types, and applications of robotic arms in this article. In the beginning of this century, robots were considered to be the future of manufacturing. Let us understand what robots are and how they are used in an industrial setup.

Adding actuators and motors to your robot arm is not a difficult task, but there are a few things you need to keep in mind. First, you need to make sure that the actuators and motors you choose are compatible with your robot’s frame. Second, you need to make sure that the actuators and motors are properly secured to the frame. And third, you need to make sure that the actuators and motors are properly wired.

Types Of Robotic Arms

The claw can grab anything from a piece of cupboard or marker up to a table tennis ball. For the claw’s inclination motor to work properly, the total mass of the claw and load shouldn’t exceed 600g. To make the connection between all electronic components, they are wired together on a breadboard, situated behind the robotic arm. It’s more complicated to connect the motor’s wires to the breadboard because they have to cross all the moving parts of the robot. It’s important for the mobility to be ensured and for the arm to be able to operate at all angles. In other words, the arm must rotate at the maximum angle without being bothered by the wires.

Conquer manufacturing in the COVID-19 era with collaborative robots

Sensors are crucial components that provide feedback to the robotic arm’s control system, enabling it to perceive and adapt to its surroundings. A robotic arm comprises several components that serve specific functions to facilitate its movement, control, and interaction with the environment. The process of loading items or products onto pallets can be automated by robotic arms. Palletizing becomes more precise, cost-effective, and predictable when the process is automated.

Best Applications of Robotic Arms

Revolute joints enable rotational movement, prismatic joints allow for linear motion, and cylindrical joints combine both rotational and linear movements. Getting back to the engineering of robotic arms, most of them have stepper motors implemented directly in the joint—or, for simplified models, in the fulcrum. Those stepper-motor models have an extremely short arm, only the radius of the axle. This causes a considerable disadvantage because the loading force will always have the point of application at the top of the boom and the only solution is to equip it with powerful motors. In this project, our model is inspired by heavy-duty machineries, such as excavators. Such equipment is capable of digging out 1.5 tons on average, being powered by high-pressure hydraulics.

Quick Links

wearable robot arms that move like spider legs prepare human interaction with cyborgs - Designboom

wearable robot arms that move like spider legs prepare human interaction with cyborgs.

Posted: Thu, 18 May 2023 07:00:00 GMT [source]

Everybody has to start somewhere, especially in 3D printing, and LittleArm is the ideal entry level project to get you hooked on 3D printed robotics. With only 3 degrees of freedom, meaning 3 points of movement on the arm, it is very easy to understand, both when 3D printing and programming. The collaborative robot is a robotic arm purpose-built for hybrid work. Certain safety features allow for significant risk reduction in hybrid work environments. This is a relatively new robot type and its uses are still being explored.

The arm needs to be able to reach all the way around, so you’ll need to make sure there’s enough space for it to move. When designing your robotic arm, it’s important to consider the weight and size of the arm. You’ll need to make sure that the arm is strong enough to support the weight of whatever it is you’re looking to lift, without being too heavy or bulky. There are many reasons why you might want to build your own robotic arm. Perhaps you need a specialized arm for a particular task or you want to create a custom design that is not available on the market.

However, its usage and importance have grown significantly in the last 10 years, mainly because every industry and individual seek automation. See, it is very important to understand that robots are not only meant to fascinate the general public, perform stunts in the street or walk and talk. In fact, robots can be programmed to perform ANY task that even a human cannot do (e.g. high precision cutting). You can also use plastics like acrylic, which will provide you with all the strength you need to hold everything together as you slowly add heavy components.

No comments:

Post a Comment